Joining in Car Body Engineering 2024

EFFECTIVE JOINING – AND DE-JOINING

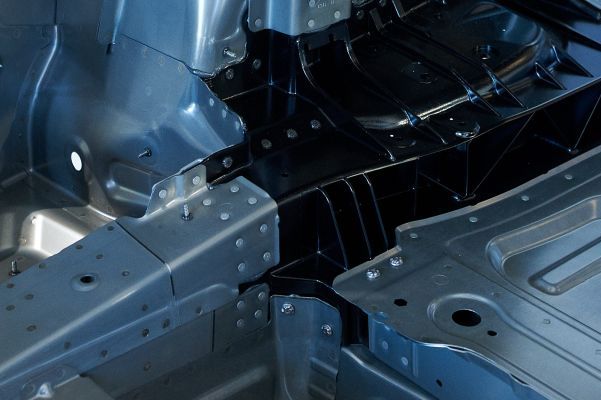

Optimising second-generation BEV and PHEV car body structures and moving towards a sustainable, carbon-neutral, yet cost-effective production probably are the two main goals in modern car body engineering, and both have much to do with optimised joining technologies and joining concepts. For instance:

- Modern battery case structures are becoming further integrated into crash load paths: How do joining concepts best reflect that?

- Megacastings are intensely discussed: When realised, how are they best joined to the rest of the structure?

- Carbon-neutral vehicle production scenarios need to include intelligent recycling concepts: Joints may need to be easily de-joinable at a vehicle’s end-of-life.

Thus, to discuss latest suggestions for optimal joining solutions, Automotive Circle’s international conference on Joining in Car Body Engineering will again discuss latest progress in all industrially relevant body shop processes with its network of experts, on April 16-18, 2024, in Bad Nauheim, Germany.

Conference Structure

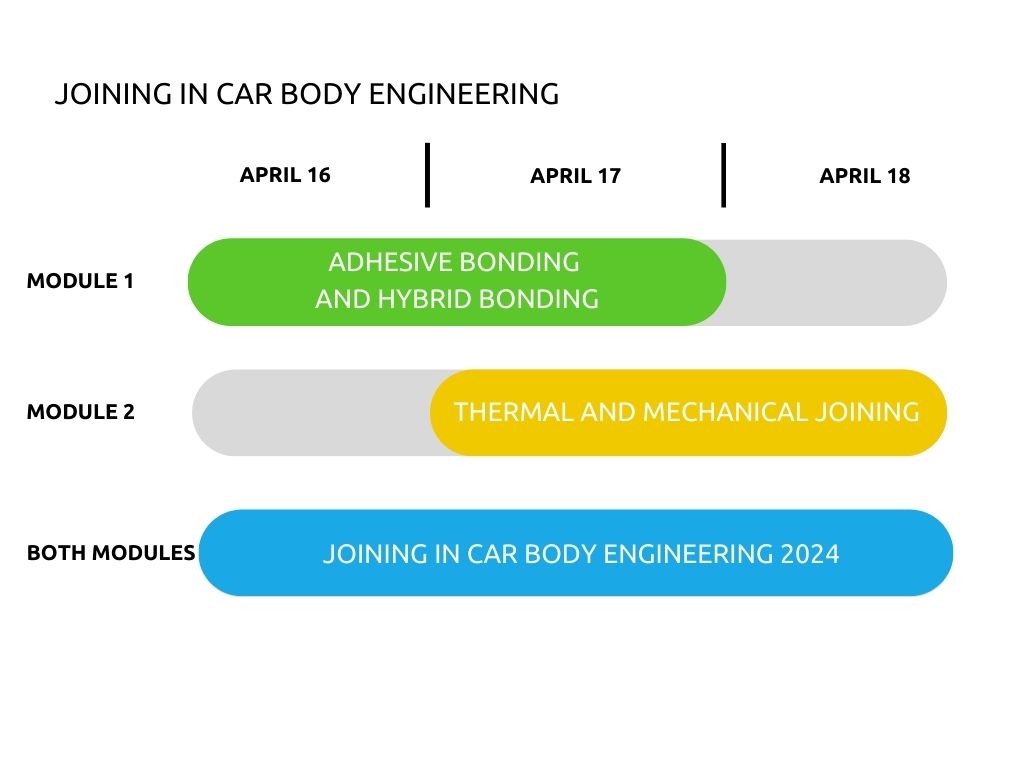

The three conference days consist of two, separately bookable modules:

Module 1, covering progress in Adhesive Bonding and Hybrid Bonding technologies, starts on the first conference day and ends in the early afternoon of the second.

Module 2, covering developments in Thermal and Mechanical Joining technologies, starts in the morning of the second conference day and ends in the afternoon of the third.

The first sessions or the second conference day feature a joint program of presentations for participants of either module, with topics that are presumed to be of interest to all participants, for instance OEM presenting the full joining concept of a recently launched car body project.

Submit a Paper

Effective joining – and de-joining

Optimising second-generation BEV and PHEV car body structures and moving towards a sustainable, carbon-neutral, yet cost-effective production probably are the two main goals in modern car body engineering, and both have much to do with optimised joining technologies and joining concepts. For instance:

- Modern battery case structures are becoming further integrated into crash load paths: How do joining concepts best reflect that?

- Megacastings are intensely discussed: When realised, how are they best joined to the rest of the structure?

- Carbon-neutral vehicle production scenarios need to include intelligent recycling concepts: Joints may need to be easily de-joinable at a vehicle’s end-of-life.

Thus, to discuss latest suggestions for optimal joining solutions, Automotive Circle’s international conference on Joining in Car Body Engineering will again discuss latest progress in all industrially relevant body shop processes with its network of experts, on April 16-18, 2024, in Bad Nauheim, Germany.

We cordially invite you to submit your proposal for a half-hour technical presentation for the conference program, reporting on your latest advances, developments and findings relevant to the conference theme.

In particular, the conference aims to present progress in the following areas:

New/improved joining solutions for…

- new materials and material combinations

- automotive castings

- battery cases and other e-mobility-related car body joining tasks with special performance requirements

- ultra-high-strength materials

- additively manufactured components

Novel, industry-ready joining technologies, for instance…

- new, non-melting welding processes

- innovative mechanical joining processes

Adhesive bonding innovations, concerning…

- new with structural, supporting or sealing adhesive bonding applications, also in hybrid combination with other joining technologies

- more precise and efficient adhesive application processes

- advances in adhesives development

More efficient production and development, via…

- improvements in throughput, stability, robustness, reproducibility, as well as maintenance or upstream process requirements

- reduction of heat input during joining, avoidance of distortions and material damage

- Smart Production / digitalization solutions in the body shop; efficient process and machinery data management and data analyses

- reliable and efficient simulations of joining processes and their integration into the virtual development environment

- new techniques for effective quality and process control

Increased flexibility and reduced complexity in the body shop, by means of…

- larger process windows and extended applicability of joining processes

- new possibilities for joining one-sided or difficult-to-access joints

- optimised body shop layouts

Sustainability and circular economy concepts, e.g. …

- comparative CO2-footprint analyses of industrial joining processes

- scope-3-sustainability: CO2 -footprint of joining elements/adhesives across the entire supply chain

- joinability of recycled, secondary materials (steel, aluminium, plastics)

- recycling-friendly joining technologies and joining concepts

- concepts and solutions for effective de-joining and debonding-on-command

- reduced energy consumption in the body shop

The three conference days will again be structured into two separate, yet overlapping modules:

Program Committee:

Module 1 – Adhesive Bonding and Hybrid Bonding (April 16-17, 2024)

Professor Dr. Klaus Dilger

Technische Universität Braunschweig

Institute of Joining and Welding (ifs)

k.dilger@tu-bs.de

Professor Dr. Christian Lammel

IFF GmbH – Induktion Fügetechnik Fertigungstechnik

christian.lammel@iff-gmbh.de

Module 2 – Thermal and Mechanical Joining (April 17-18, 2024)

Professor Dr. Stefan Böhm

University of Kassel \ Institute of Production Technology and Logistics

s.boehm@uni-kassel.de

Dr. Dirk Meine

Automotive Circle

T +49 (0)511 9910-319

dirk.meine@vincentz.net

The members of the Program Committee will be happy to answer any questions you may have about your submission.

We cordially invite you to submit your proposal for a half-hour technical presentation at Joining in Car Body Engineering 2024. Please send us, using our online submission form, a concise, non-promotional, English-language abstract outlining your results

by October 30, 2023.

Based on your abstract, in collaboration with the OEM Advisory Board of the conference, we will evaluate your proposal. In that process, the novelty of your results, their industrial relevance and the engineering-oriented, technical character of your proposal will be of particular importance.

If your contribution is accepted, we are pleased to invite one speaker from your company to take part in the corresponding conference module, i.e. exempt of the conference fees and including hotel accommodation.

Further key dates

- Notification of acceptance of your proposal: mid-November 2023

- Publication of the conference programme: early January 2023

- Submission of your (English-language) presentation documents as a pdf for the conference proceedings: March 16, 2024

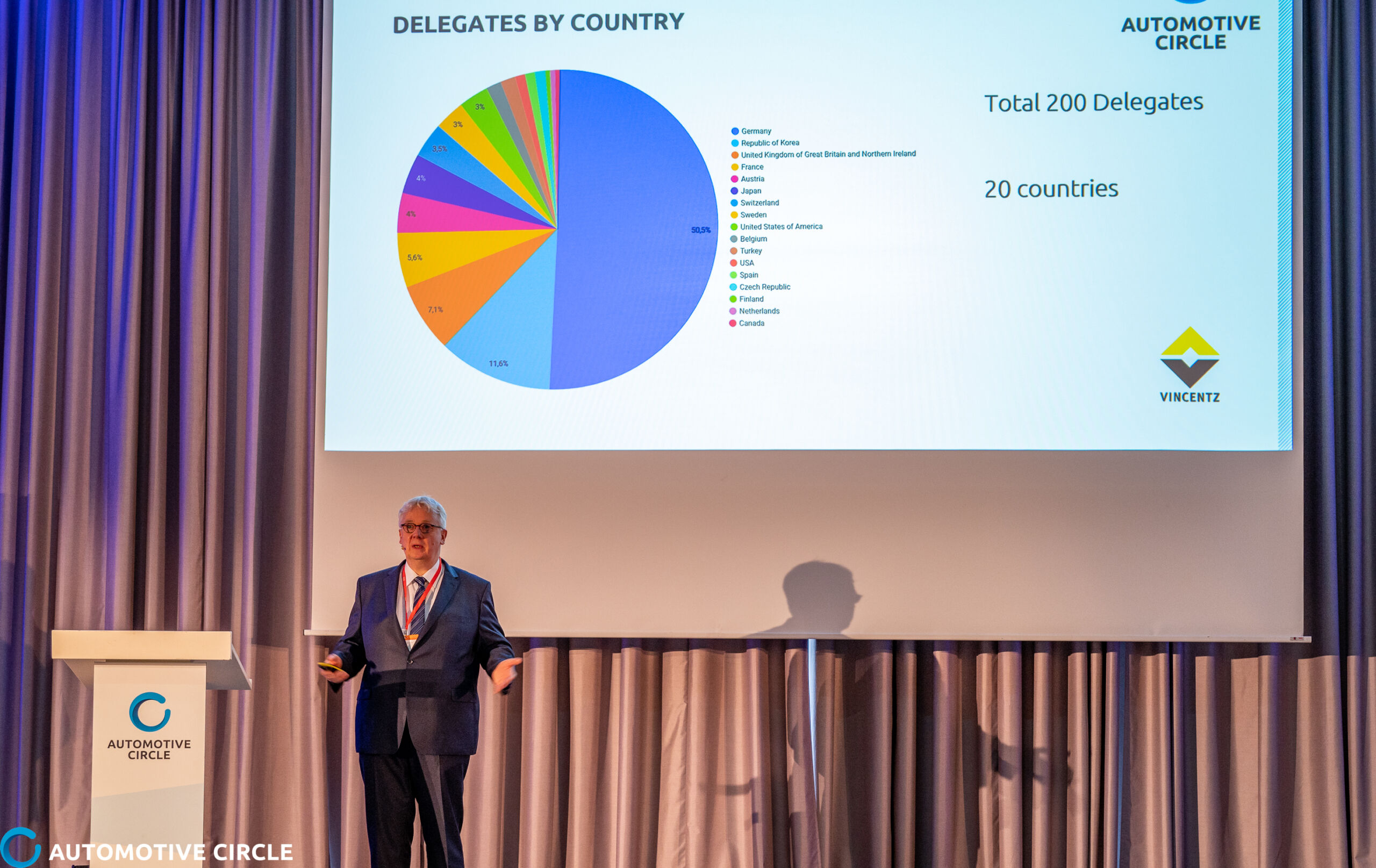

Participants

Exhibition & Sponsoring

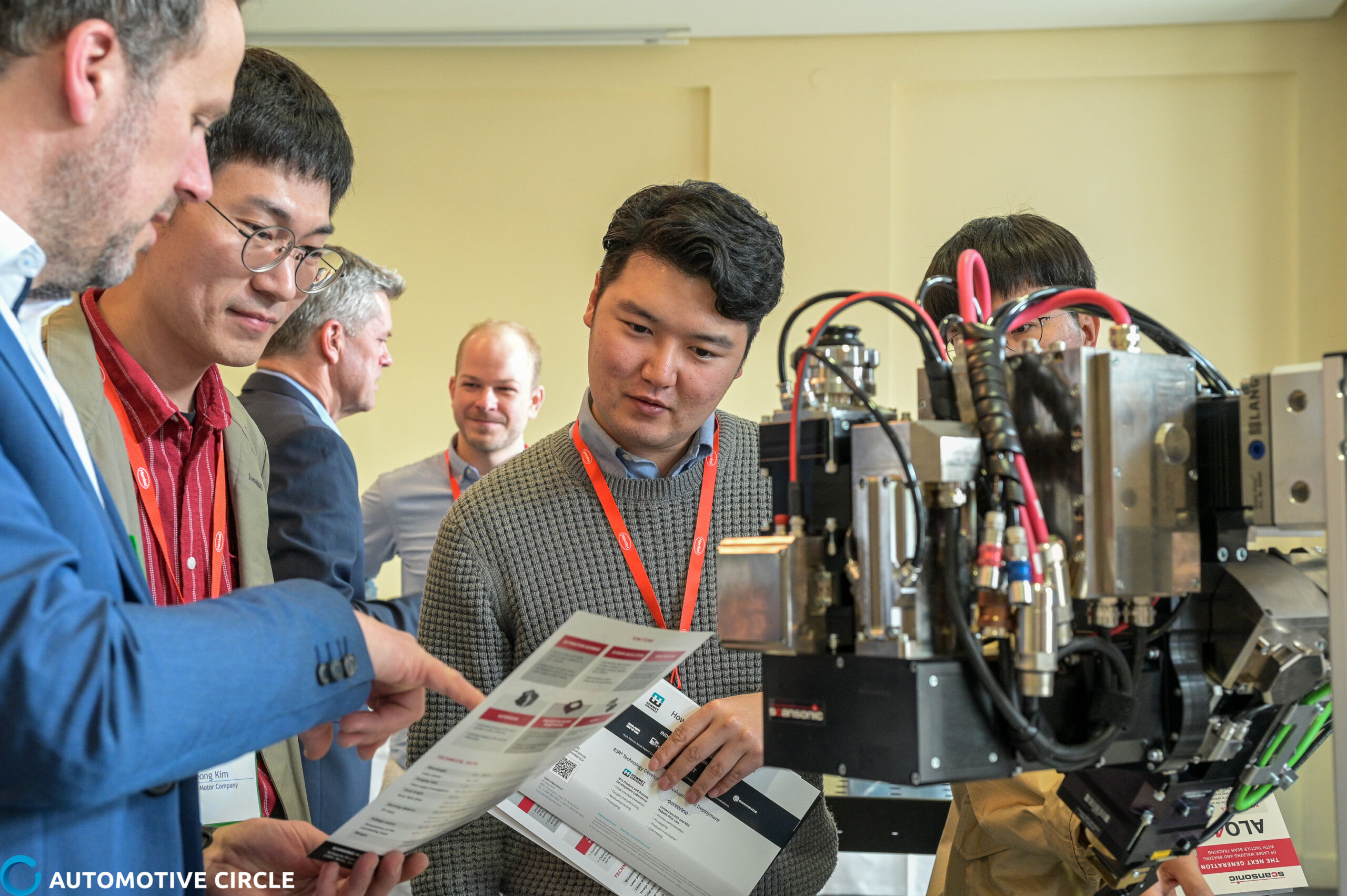

Become a sponsor or exhibitor

Take advantage of the high coverage of the Automotive Circle and profit from the sponsoring options before and during the events. Show your competence and services, matching the conference subjects, to the numerous car body engineers of international OEM. Thus, you are strengthening your brand awareness in the automotive industry!

Come on board as an exhibitor or sponsor and benefit from this excellent platform to strongly promote your company’s capabilities as a reliable supplier!

Check out the various exibition and sponsoring options!

Review

Flashback 2023

More Information

Your Contacts