Car Body Parts

from development to production

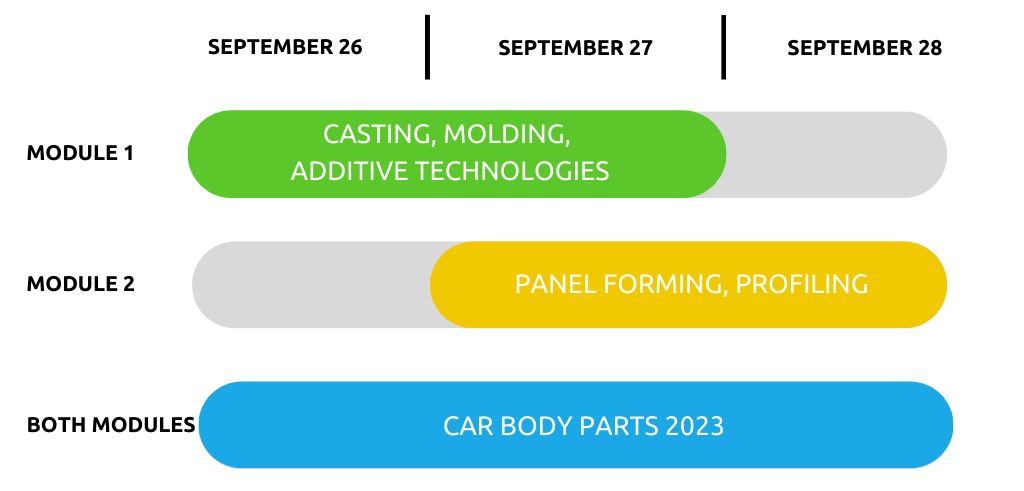

Module 1: Casting, Molding, Additive Technologies

September 26/27

Module 2: Panel Forming, Profiling

September 27/28

What is the “right”mix of technologies?

How to best produce the parts that make up a car body – structural, load-bearing parts as well as complex-shaped outer skin panels? That is the question newly addressed by the three-day Automotive Circle conference Car Body Parts, discussing all engineering aspects concerning the improvement of industrially relevant processes to do with their production, in the tool shop, press shop or foundry.

Grouping these processes, the conference is structured into two separate, yet overlapping modules:

Module 1 – Casting, Molding, Additive Technologies, on September 26/27, focuses on primary forming technologies for metals and plastics, e.g.:

- Light metal castings and mega-castings: What is technically possible? What are the pros and cons of their use? What challenges exist and how may they be overcome?

- To what extent can additive manufacturing technologies efficiently be applied in the production of car body parts?

Module 2 – Panel Forming, Profiling, onSeptember 27/28, continues the tradition of Automotive Circles Forming in Car Body Engineering conference and addresses progress in the panel-forming press plant and tool shop, as well as in other secondary forming technologies, such as profile forming, roll or blow forming:

- How can efficiency, flexibility, precision be improved in the press plant, tryout and tooling processes?

- What progress has been achieved in steel or aluminium hot forming processes, what improvements have been made in the cold forming of high-strength materials? How can new levels of design freedom be realised?

- What is the latest news in press technology?

- What progress has been made in profiling solutions and how can they be applied in modern car body architectures, especially in next-generation BEV?

In both conference modules, advances in hardware process developments as well as in process simulation will be discussed. When considered useful, demonstrator parts accompanying a presentation are highly welcomed.

On 27 September, the overlapping joint session of both modules features progress reports considered to be of interest to participants of either conference module, featuring OEM progress reports and innovations suggesting new answers to the title challenge above: Finding the right mix of car body part production technologies for today’s car body concepts.

Conference Agenda

Tuesday, September 26

| 09.00 am | Welcome and introduction to conference Module 1 | Dr. Dirk Meine, Automotive Circle, DE |

CASTING CAPABILITIES |

||

| 09.15 am | Gigapress under body casting cell | John Stokes, Idra Srl., IT |

| 09.45 am | As-cast engineering and prototyping of large integrated structural castings | Kentaro Higaki, Kimura Foundry Co., Ltd., JP; Dr. Joachim Gundlach, Grunewald GmbH & Co KG, DE |

| 10.15 am | Sustainable megacasting production for the body-in-white of tomorrow | Hermann Roos, Bühler Group, CH |

| 10.45 am | Meet the Speakers | Coffee and contacts | |

CASTING CHALLENGES |

||

| 11.30 am | Die casting challenges in aluminium automobile lightweight body parts manufacturing using HPDC process | David Lorenz, ESI Germany GmbH, DE |

| 12.00 pm | Mega, giga, hyper – challenges of a new dimension: 3D straightening of structural castings | Philipp Hettich, Laubinger + Rickmann GmbH & Co. KG, DE |

| 12.30 pm | The project MeGiCast

– Follow-up of the Megacasting vs Multi-Material-Mix discussion held at Car Body Parts 2022 – |

Simon Frank, AIT Austrian Institute of Technology, Center for Low-Emission Transport, AT; Prof. Thilo Röth, ACA Invest GmbH, DE |

| 01.00 pm | Live polls in the auditorium | |

| 01.15 pm | Meet the Speakers | Lunch break | |

CASTING PROCESS IMPROVEMENTS |

||

| 02.30 pm | Weight-neutral substitution of magnesium by aluminum in die casting through innovative 4-plate mold technology | Dr. Thomas Kopp, Thomas Pöppl, BMW Group, DE |

| 03.00 pm | Innovative vacuum dosing technology for sustainable mega & giga foundries | Roger Rapp, Meltec Industrieofenbau GmbH, AT |

| 03.30 pm | Meet the Speakers | Coffee and contacts | |

| 04.15 pm | – online presentation –

Advanced manufacturing of conforming cooling molds |

Dr. Haneen Daoud, Neue Materialien Bayreuth GmbH, DE |

| 04.45 pm | Accelerating the product development process of overmolded structures via Robotic Screw Extrusion Additive Manufacturing | Timo Huse, German Aerospace Center (DLR), Institute of Vehicle Concepts, DE |

| 05.15 pm | Meet the Speakers | Get-Together | |

| 06.30 pm | Networking Night Module 1 | |

Wednesday, September 27 |

||

| Joint Sessions | ||

| 09.00 am | Welcome and introduction to conference Module 2 | Dr. Dirk Meine, Automotive Circle, DE |

OEM FOUNDRY ACTIVITIES |

||

| 09.15 am | Renault BIW by casting |

Franck Gaté, Renault, FR |

| 09.45 am | – online presentation –

ZEEKR 009 Megacasting rear floor |

Tianqi Li, Jian Wang, Yadong Song, ZEEKR Automobile, CN |

| 10.15 am | Large in-house HPDC aluminium casting for next generation body in white design at Volvo Cars

+ Rear floor demonstrator part |

Michelle Khoo, Volvo Car Company, SE |

| 11.00 am | Meet the Speakers | Coffee and contacts | |

PANEL DISCUSSION |

||

| 11.45 am | Live Poll Session: Megacastings – a game changer for the industry? |

Questioning the conference audience on their opinions, experiences and evaluations |

| 12.30 pm | Meet the Speakers | Lunch break | |

CONCEPT INNOVATIONS |

||

| 01.45 pm | Smart search engine to unlock the full potential of technical databases | Charles Zgheib, Brightclue, FR |

| 02.15 pm | Automatic inline surface inspection in press shop and body shop | Hubert Lechner, Carl Zeiss Automated Inspection GmbH, DE |

| 02.45 pm | Sustainable steel solutions to simplify vehicle design and production | Jesse Paegle, ArcelorMittal S.A., FR |

| 03.15 pm | Meet the Speakers | Coffee and contacts | |

End of Module 1 |

||

Wednesday, September 27

|

||

| 09.00 am | Welcome and introduction to conference Module 2 | Dr. Dirk Meine, Automotive Circle, DE |

OEM FOUNDRY ACTIVITIES |

||

| 09.15 am | Renault BIW by casting |

Franck Gaté, Renault, FR |

| 09.45 am | – online presentation -ZEEKR 009 Megacasting rear floor | Tianqi Li, Jian Wang, Yadong Song, ZEEKR Automobile, CN |

| 10.15 am | Large in-house HPDC aluminium casting for next generation body in white design at Volvo Cars

+ Rear floor demonstrator part |

Michelle Khoo, Volvo Car Company, SE |

| 11.00 am | Meet the Speakers | Coffee and contacts | |

PANEL DISCUSSION |

||

| 11.45 am | Live Poll Session: Megacastings – a game changer for the industry? |

Questioning the conference audience on their opinions, experiences and evaluations |

| 12.30 pm | Meet the Speakers | Lunch break | |

CONCEPT INNOVATIONS |

||

| 01.45 pm | Smart search engine to unlock the full potential of technical databases | Charles Zgheib, Brightclue, FR |

| 02.15 pm | Automatic inline surface inspection in press shop and body shop | Hubert Lechner, Carl Zeiss Automated Inspection GmbH, DE |

| 02.45 pm | Sustainable steel solutions to simplify vehicle design and production | Jesse Paegle, ArcelorMittal S.A., FR |

| 03.15 pm | Meet the Speakers | Coffee and contacts | |

| End of Module 1 | ||

Module 2 (continued) |

||

INCREASING PROCESS EFFICIENCY |

||

| 04.00 pm | – online presentation –

Efficiency by design – The application of a smart stamping process engineering concept in the BiW process definition |

Gianfranco Ruggiero, AutoForm Engineering, IT |

| 04.30 pm | A novel stamping method to reduce trimming scrap by 75% on applicable BiW components | Christopher Cleaver, DeepForm Ltd., UK |

| 05.00 pm | Material reduction in additively manufactured sheet metal forming tools | Yannick Taschbach, Laboratory for Machine Tools and Production Engineering (WZL) of RWTH Aachen University, DE |

| 05.30 pm | The influence of surface cleaning on scrap rates and production costs of car body parts | Daniel Gottschall, Wandres GmbH micro-cleaning, DE |

| 06.00 pm | Meet the Speakers | Get-Together | |

| 07.00 pm | Networking Night Module 2 | |

Thursday, September 28 |

||

| Module 2: Panel forming, profiling (continued) |

||

PANEL FORMING PROCESS INNOVATIONS |

||

| 09.00 am | – online presentation –

Improving of productivity using direct water quenching in hotstamping of ultra-high strength steel parts |

Yujiro Mitsui, Subaru Corporation, JP; Yasutaka Suzuki, Toa Industries Co., Ltd., JP |

| 09.30 am | Application potential of new hot forming steels under consideration of manufacturing technologies | Janko Banik, Dr. Dirk Rosenstock, thyssenkrupp Steel Europe AG, DE |

| 10.00 am | New stamping technology for lightweight materials – Application of warm forming for high strength aluminium | Jens Aspacher, Schuler Pressen GmbH, DE; Dr. Li-Liang Wang, Department of Mechanical Engineering, Imperial College London, UK |

| 10.30 am | Meet the Speakers | Coffee and contacts | |

| 11.15 am | Possibilities of sustainable heating methods for press hardening processes | André Jungeilges, Paderborn University, Chair of Automotive Lightweight Design (LiA), DE |

| 11.45 am | Laser welded blank solutions for subframe chassis | Kevin Luttenschlager, ArcelorMittal Tailored Blanks, FR |

| 12.15 pm | The fully digital approach for optimized aluminum components | Dr. Patrick Böhler, Constellium Singen GmbH, DE |

| 12.45 pm | OEM summaries |

OEM Advisory Board experts on their learnings from the conference and foreseeable challenges in car body part production. |

| 1.00 pm | Concluding remarks and end of the conference | Dr. Dirk Meine, Automotive Circle, DE |

| 01.15 pm | Farewell lunch | |

All times in CEST (UTC+2)

Conference Program is subject to change

Status as of: September 21, 2023

Participants

Exhibition & Sponsoring

Exhibitors and sponsors on site

Become a sponsor or exhibitor

Take advantage of the high coverage of the Automotive Circle and profit from the sponsoring options before and during the events. Show your competence and services, matching the conference subjects, to the numerous car body engineers of international OEM. Thus, you are strengthening your brand awareness in the automotive industry!

Come on board as an exhibitor or sponsor and benefit from this excellent platform to strongly promote your company’s capabilities as a reliable supplier!

Check out the various exibition and sponsoring options!

![Imke_Rotermund[1]](https://stage.automotive-circle.abtdgt.de/wp-content/uploads/2023/01/Imke_Rotermund1.png)

More information

Your Contacts