Joining in Car Body Engineering 2023

Adjusting priorities

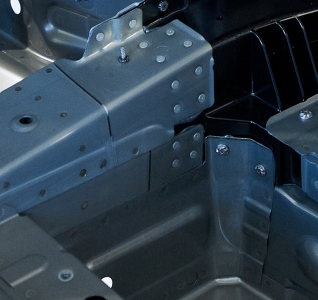

In the midst of a number of previously unimagined crises affecting the automotive industry, some re-evaluation and adjustment of priorities in automotive construction and planning is not an unlikely consequence. That also concerns body shop processes, naturally: Avoidance of critical dependencies, or greater flexibility in production have become rather important. At the same time, the need to analyse, understand and advance the sustainability of automobile production processes has become prominent and affects engineering decisions on materials and joining technologies as well. With all this going on, however, no OEM will compromise the safety or quality of its developments. So, for the body shop, the task is to find the best technical solutions that fulfil all requirements – at a viable cost.

Thus, from April 18 to 20, 2023, Automotive Circle’s international conference Joining in Car Body Engineering will once again discuss latest progress in all industrially relevant body shop processes with its network of experts, looking into the possibilities of new joining technologies, of widened application windows for established ones, as well as into ideas and examples for optimised, more efficient body shop concepts.

Visit us in Bad Nauheim, we look forward to seeing you!

Don’t miss any updates by following our Hashtag: #ACJoining

Conference Agenda

Module 1: Adhesive bonding and hybrid bonding

| 08:40 am |

Welcome and conference introduction |

Dr. Dirk Meine, Automotive Circle, DE |

Bonding concepts |

||

| 09:00 am |

Adhesive bonding works – even with few joining points |

Moritz Huf, BMW Group, DE; Dr. Holger Fricke, Fraunhofer Institute for Manufacturing Technology and Advanced Materials (IFAM), DE |

| 09:30 am |

Rapid pre-curing of epoxy-based structural adhesives for body in white applications |

Güven Celebi, Technische Universität Braunschweig, Institute of Joining and Welding, DE |

Sustainability considerations |

||

| 10:00 am |

The Global Goal to contribute to CO2 footprint reduction in Automotive Production / Smart materials and solutions in design, production and logistics for Body Shop and e-mobility Systems |

Holger Schuh, Michael Klotz, Henkel AG & Co KGaA, DE |

| 10:30 am | Meet the Speakers / Coffee and contacts | |

| 11:15 am |

Sustainability in the life cycle of body shop adhesive bonding |

Urs Rheinegger, Sika AG, CH |

| 11:45 am |

New advanced curing structural adhesives enabling modern electric vehicle design and significant energy savings in body shop |

Dr. Felix Koch, Stefan Schmatloch, DuPont Specialty Electronic Materials Switzerland GmbH, CH |

| 12:15 pm |

VIRTUAL PRESENTATION:

|

Gurkan Sonmet, Jaguar Land Rover Ltd., UK |

| 12:45 pm | Meet the Speakers / Lunch break | |

Adhesive application and quality control |

||

| 02:00 pm |

Packaging solutions to support precision, consistency and environmental impact of adhesive application |

Christoffer Lampa, Peter Larsson, Fluid-Bag Ltd., FI |

| 02:30 pm |

Future trends in dispensing technology |

Sebastian Gries, Dürr Systems AG, DE |

| 03:00 pm |

Innovative process monitoring in aluminum sheet production for maximum bonding performance |

Dr. Ramona Tosone, AMAG Austria Metall AG, AT |

| 03:30 pm | Meet the Speakers / Coffee and contacts | |

| 04:15 pm |

Application concept of a new vibration-based measurement technique for the in-line quality assurance of structural bonded joints in car bodies within the scope of DIN 2304 |

Christian Gundlach, Technische Universität Braunschweig, Institute of Joining and Welding /Open Hybrid LabFactory e.V., DE |

Adhesive bonding in e-mobility |

||

| 04:45 pm |

Rheology-based classification of adhesives for stencil printing of fuel cell sealings |

Fabiano Indicatti, Robert Bosch GmbH, DE |

| 05:15 pm |

Laser-based preparation for adhesive joining and electrical bonding of battery housings |

Edwin Büchter, Clean-Lasersysteme GmbH, DE |

| 05:45 pm | Meet the Speakers / Get together | |

| 07:00 pm | Networking Night Module 1 |

*Subject to change. Status as of March 29, 2023

Module 1: Adhesive bonding and hybrid bonding (continued)

Module 2: Thermal and mechanical joining

– Joint session of both modules –

| 08:30 am |

Welcome and introduction to Module 2

|

Dr. Dirk Meine, Automotive Circle, DE |

OEM joining solutions

|

||

| 08:50 am |

Low bake material solutions as an enabler for electrification and CO2 neutrality |

Laurent Tollier, Raynald Bougnot, Stellantis NV, FR |

| 09:20 am |

Multi-sensor concept for inline monitoring of the influencing factors on the adhesive filling level during automotive hem flange bonding |

Kay Hermannsdörfer, Audi AG, DE; Lennart Stohrer, Laboratory for Machine Tools and Production Engineering (WZL), RWTH Aachen University, DE |

| 09:50 am |

New production route for aluminium doors |

Christian Borowetz, Volkswagen AG, DE |

| 10:20 am | Meet the Speakers / Coffee and contacts | |

Challenging joints

|

||

| 11:00 am |

Challenges for future integrations of joining technologies in an increasingly volatile environment from the supplier’s perspective |

Dr. Vitalij Janzen, Arnold Umformtechnik GmbH & Co. KG, DE |

| 11:30 am |

Increased flexibility for single-sided joining by a noise-reduced bolt-setting process and innovative fastener developments |

Dennis Henke, Böllhoff Verbindungstechnik GmbH, DE |

| 12:00 pm |

Overview of the Range Rover and Range Rover Sport joining technologies |

Faizan Arshad, Jaguar Land Rover Ltd., UK |

| 12:20 pm |

Enabling joining of aluminium castings for mixed material design with Self-Pierce-Riveting (SPR) |

Dr. Matthias Wissling & Dr. Christian Reis, Stanley Industrial – Tucker GmbH, DE |

| 12:45 pm | Meet the Speakers / Lunch break | |

New thinking in QC and production

|

||

| 02:00 pm |

Non-destructive testing of friction element welded joints using active thermography |

Toni Müller, Ejot SE & Co. KG, DE |

| 02:30 pm |

The AI-Inspector: quality check in body-in-white production with machine learning – the third eye for the worker |

Dr. Matthias Reichenbach, Moises Araya-Martinez, Mercedes-Benz AG, DE |

| 03:00 pm |

Integrated processes – Welding in the composite tool inside the servo press |

Waldemar Garus, Nimak GmbH, DE; Thomas Teipel, Heru Werkzeugbau GmbH & Co. KG, DE |

| 03:30 pm | Meet the Speakers / Coffee and contacts | |

| End of Module 1

Module 2: Thermal and mechanical joining (continued) |

||

Battery case joining

|

||

| 04:00 pm |

Combining tactile laser welding with beam wobbling to improve weld quality of 6xxx aluminum alloys for manufacturing of e-mobility parts |

Dr. Axel Luft, Scansonic MI GmbH, DE; Prof. Pasquale Franciosa, WMG, University of Warwick, UK |

| 04:30 pm |

Mechanical fastening solutions for battery trays: design, testing and validation |

Dr. Amer Mahlme, Profil Verbindungstechnik GmbH, DE |

New old joining technologies

|

||

| 05:00 pm |

An innovative thermally decoupled welding insert to join all multi-material combinations on a standard BIW assembly line |

Sean Farrell, Gaming Engineering, FR |

| 05:30 pm |

Innovative thread technology as the main requirement for cast aluminium structures in modern vehicle construction |

Michael Stumpf, Böllhoff Verbindungstechnik GmbH, DE |

| 06:00 pm | Meet the Speakers / Get together | |

| 07:00 pm | Networking Night Module 2 |

*Subject to change. Status as of March 29, 2023

Module 2: Thermal and mechanical joining (continued)

Using resistance |

||

| 08:30 am |

Efficient car body production — current challenges in resistance spot welding |

Dirk Altnau, Torsten Wegner, BMW Group, DE |

| 09:00 am |

Teach caps for resistance spot welding and clinching |

Florian Auernhammer, Volkswagen AG, DE |

| 09:30 am |

Resistance Spot Riveting of mixed materials |

Graham Musgrove, Howmet Fastening Systems, US; Udo Schulz, CenterLine Germany GmbH, DE |

| 10:00 am | Meet the Speakers / Coffee and contacts | |

Mechanical innovations |

||

| 10:45 am |

Sustainability and versatility of self-piercing riveting – Innovative approaches and future trends |

Clara-Maria Kuball, Friedrich-Alexander-Universität Erlangen-Nürnberg, Department of Mechanical Engineering, Institute of Manufacturing Technology (LFT), DE |

| 11:15 am |

Volumelock: a new method of measuring SPR cross sections to rank solutions and predict joint strength |

Dr. Paul Briskham & Lewis Jepps, Atlas Copco IAS UK ltd, UK |

| 11:45 am |

New self-piercing hat nut for tight mechanical joints in steel and aluminum car body parts |

Dr. Markus Hirschmann, Richard Bergner Verbindungstechnik GmbH & Co. KG, DE |

| 12:15 pm |

Vision Pre-Hole Centering to improve flow drill fastening processes with pre-holes |

Andreas Kiefer, Ali Jamehbozorg, Atlas Copco – IAS Division |

| 12:45 pm | Meet the Speakers / Lunch break | |

| 02:00 pm |

A new laser-assisted mechanical joining system with industrial production readiness |

Klaus Krastel, IPG Laser GmbH, DE; Dr. Wolfgang Pfeiffer, Tox Pressotechnik GmbH & Co. KG, DE |

Press hardened steels |

||

| 02:30 pm |

Analysis of welded joint fatigue performance on press hardening steel |

Prof. Hardy Mohrbacher, Niobelcon b.v., BE |

| 03:00 pm |

New hot forming steels – application potential under consideration of joining processes and manufacturing technologies |

Janko Banik & Johan Neher, Thyssenkrupp Steel Europe AG, DE |

| 03:30 pm |

OEM conclusions |

The conference’s OEM Advisory Board experts on trends and current challenges in car body joining technology. |

| 03:45 pm |

Farewell address and end of the conference |

*Subject to change. Status as of March 29, 2023

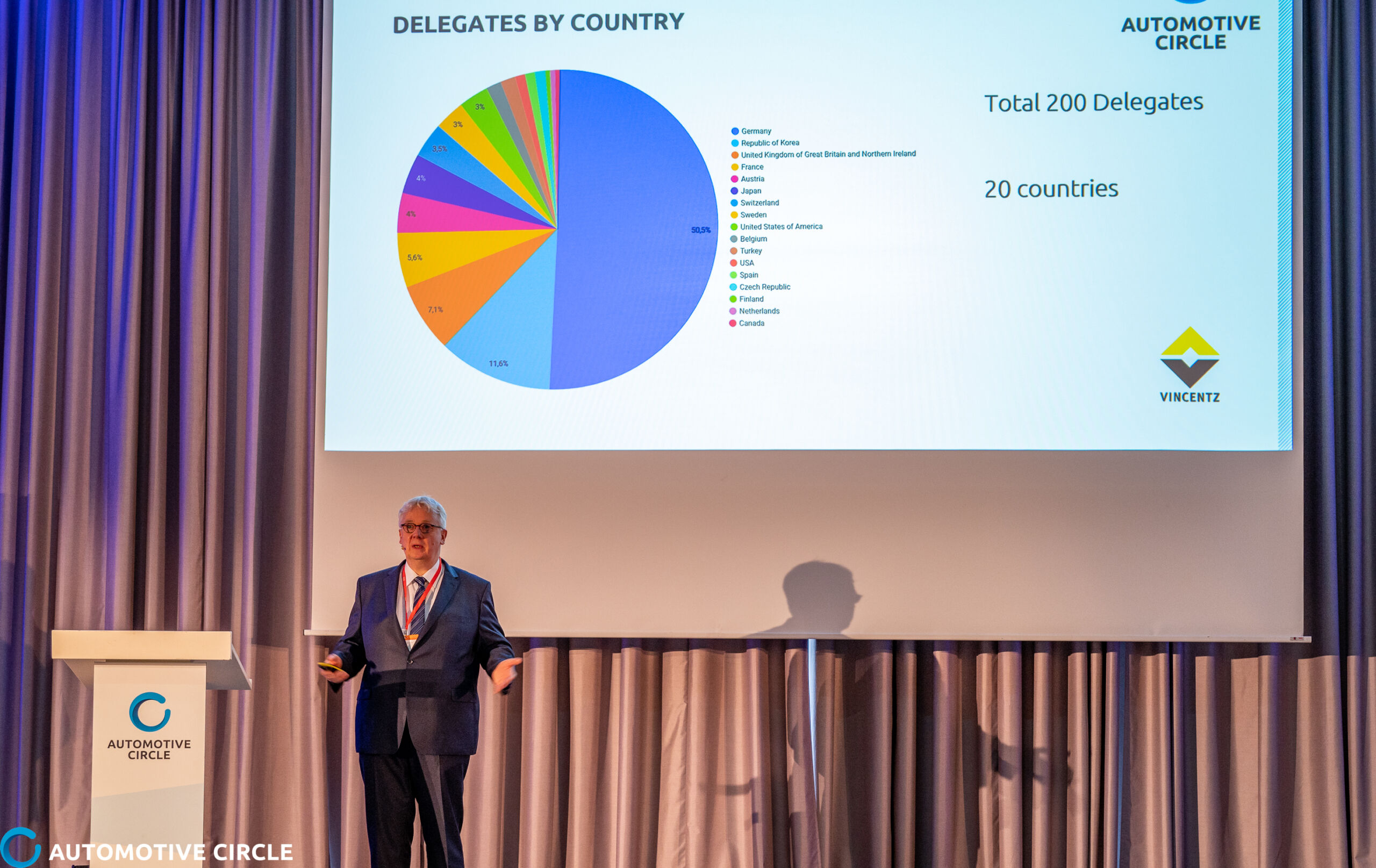

Participants

Review

Flashback 2023

Your Contacts